"When you need a fabricator for your complex assemblies"

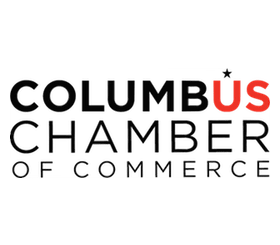

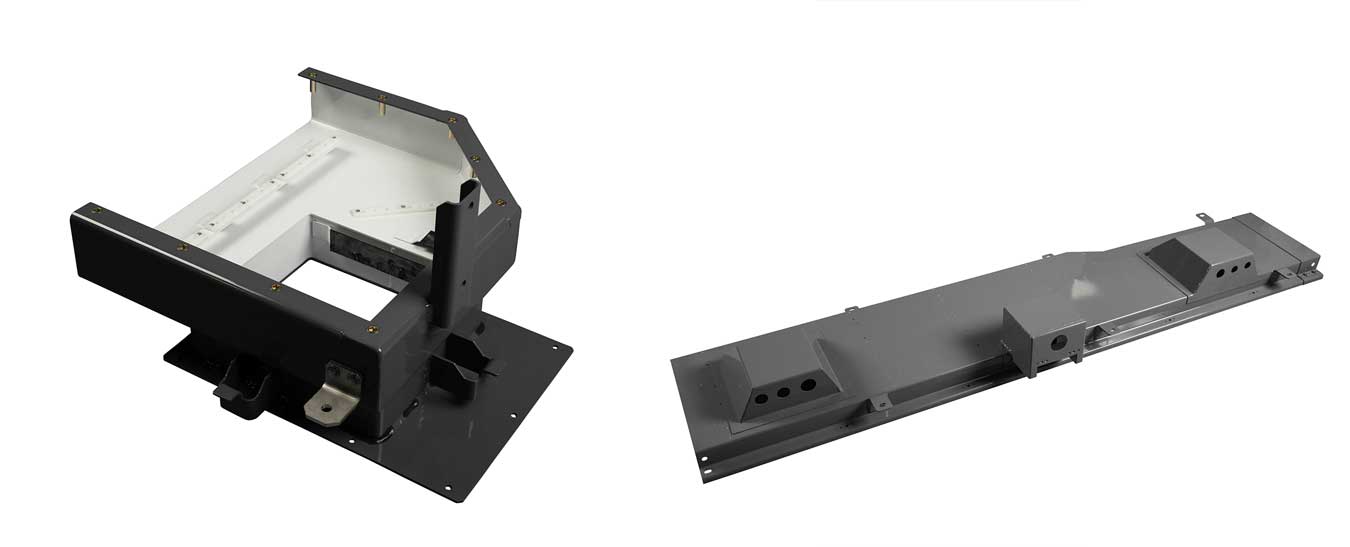

Client: Mass-Transit Railcar OEM

Objective: Production of housing and cover assemblies for railcar interiors and undercarriages.

The process begins with the production of all stainless steel and aluminum components using an array of equipment, including 2D lasers, press brakes, chamfer drill presses and a deburring machine. Final assembly is performed either via our SPOT-welding robotic cell or manual TIG welding. Painting is outsourced.

Our extensive history serving the mass-transit railcar industry has honed our team of AWS-certified welders, process engineers, fabricators and quality technicians to readily take on the many complex assemblies used in present-day railcars.